James Nordstrom is the founder of 3DPrintClean, which specializes in 3D Printer Filtration and Safety Enclosures. They are looking to solve various issues in terms of safety and public health within the industry of 3D Printing.

What has gotten you to where you are now?

I spent 20 years in software IT, but I always had a fascination in engineering. I did a robotics project in 2010 and that taught me a lot about CAD and various skills. I also worked for various startups in my career.

Can you explain what you do with 3DPrintClean?

My brother’s girlfriend was into comic con. She was building a huge costume with 3D printed parts. Then my brother and I found research on filtration from the Illinois Institute of Technology on various articles on how emissions of 3D printing can be detrimental to one’s health. We then were able to build a prototype quickly. Then we became very involved as one of the first advocates of this. It was interesting as we first were selling a lot to Canada and Europe as they were very health sensitive. Then eventually America started to come around as well. This then allowed us to go more in depth with our solution as well. We started thinking about things like fire safety.

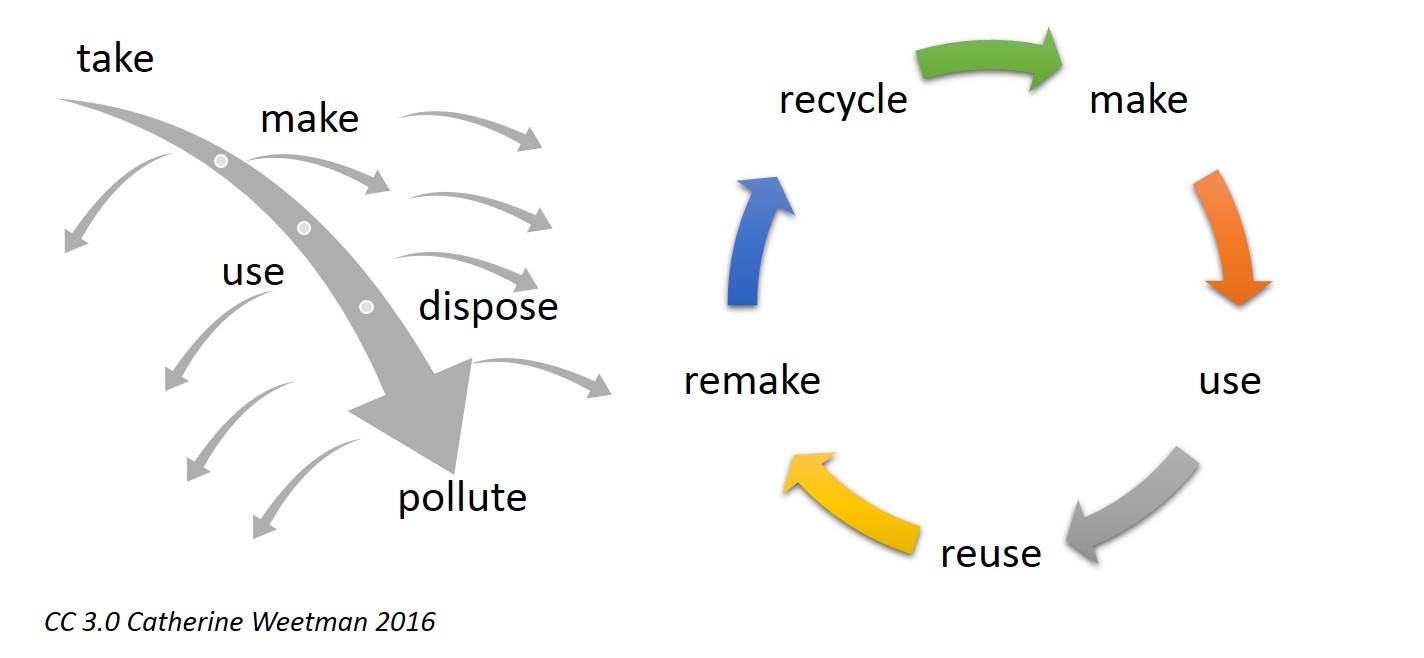

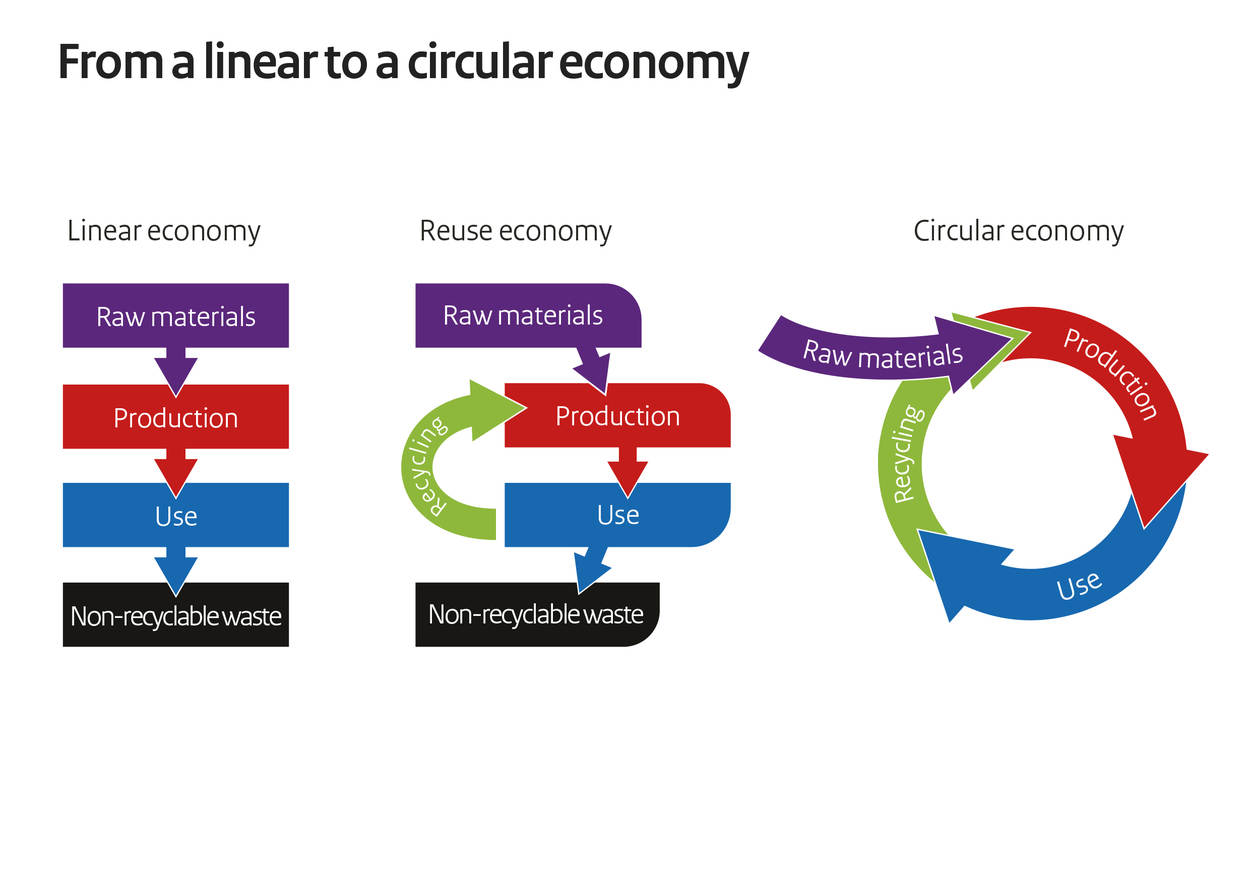

What are your thoughts on sustainability and the circular economy?

This is definitely something we have been thinking about. We have learned a ton about this. The amount of plastic produced with the plastic part and the scaffolding parts is large. PLA is a much better recycling material than typical plastic. If you put it in a landfill, it will not be recyclable. Recycling companies do not know what to do with the material. People use different filament types and that makes them impossible to recycle. There is some great work done in the space from companies like Filabot.

What are some typical areas of concern when a 3D printer is producing a part in terms of sustainability and safety?

Safety is our bread and butter. Filtration and unauthorized access are big areas of concern. I have seen teachers who have had problems as well. I also think it is important to know about the safety behind these materials as well. Resins are a huge problem as well. Metal Sintering powders are also very explosive as well. It is important to keep these things in mind when dealing with 3D Printing and the future of its development.

Can you talk about the technology behind 3DPrintClean’s fume and particle filtration system?

We developed proprietary solutions. Most filters do not do well based on the size of the particle. These go straight to your bloodstream when you inhale them. The filter tech addresses various nanoparticles. We also address VOC’s. We pride ourselves on being experts in this field. We constantly look for new ways to filter various products.

The filament side is really interesting. Then are loads of printers that are doing great in terms of safety, but some printers are prone to fire. One thing that shocked us about the filaments is that most printers state that they should be used in a well ventilated area. Everyone also moved to PLA because they thought it was safe.

PLA does produce ultrafine particles as well. This does not mean it is safe. It is especially important in the school when you have growing lungs. A dean from a school we go to used to be a toxicologist and she instantly realized the value of the work we were doing. She then mandated all of their 3D Printers should be using our ventilation systems.

What are some simple things we should all be aware of in terms of 3D printing safety?

I think knowing the basics about mechanical properties is important. Knowing about the heated head is important. Material handling is important especially in SLA printers. Really teaching people to wearing respirators is important. General post processing is important, but knowing about acetone as a flammable object is important. A lot of people used to make their own glue for the bed. One would take acetone and some plastic to make a slosh, but this is actually very dangerous. We realize that with all of these safety concerns taken care of it helps to make a higher quality print. When we have our enclosed system, it allows for air to not affect the temperature.

How important is public health within the growing trend of consumers using 3D printers?

Extremely. It is super critical. People are getting toys and they do not understand them. We have to make people aware of the challenges. It is not something you just put in your bedroom. Professional labs are important to be kept safe. How to be around these items is important. ABS is also flammable, so we have to think about all of these ignition spots.

What are the future plans of 3DPrintClean?

We are continuing to evolve our filters. We will also launch new sizes for printers. We will also continue to build new accessories. We will continue to improve and evolve based on what customers want. People have asked us for fire alarms and text communication to help them know about problems as a remote user. We are just making sure we cover our bases in terms of how we can aid our customers and their safety.