In the industrial world, 3D printed jigs and fixtures are truly unsung heroes. Both jigs and fixtures are types of tools that are used to control the operation of another instrument. However, a fixture sets itself apart in that it’s mainly used to hold another tool or device in place during the manufacturing process.

As a manufacturer, in any industry, you rely on essential components like jigs and fixtures to get the job done. The difference is that these days, more and more manufacturers are realizing massive productivity increases and lowered costs by 3D printing these essential manufacturing aids.

In this series of articles, we will layout the benefits of using additive manufacturing to produce Jigs & Fixtures. The first part will focus on Jigs. To find out more about how you can harness the potential of 3D printing jigs and fixtures to increase productivity and reduce costs, read on.

Jigs 101

Jigs are custom-made tools that hold in place and control the motion of other devices or parts in the manufacturing process. Unlike a fixture, a jig lets manufacturers expedite the assembly or construction of a product by allowing for greater interchangeability and repeatability.

It should come as no surprise, then, that jigs are a staple in virtually all mass-production systems in the developed world. However, small and medium-sized firms traditionally haven’t been able to create custom-made jigs until the arrival of 3D printing technologies.

Why 3D Print Jigs and Fixtures?

Most companies cannot afford to splurge on traditionally manufactured jigs and fixtures to add to their assembly lines or build processes. Thanks to the advent of additive manufacturing, productivity-enhancing tools such as jigs, fixtures, and grips can now be produced at a fraction of the cost of their traditionally made counterparts.

Producing jigs and fixtures via 3D printing is a highly cost-effective means of speeding up your assembly times and reducing labor costs. Plus, on-demand jig and fixture production eliminates upfront inventory requirements. Instead, digital inventory allows for seamless updates and revisions to keep your equipment working the way it should.

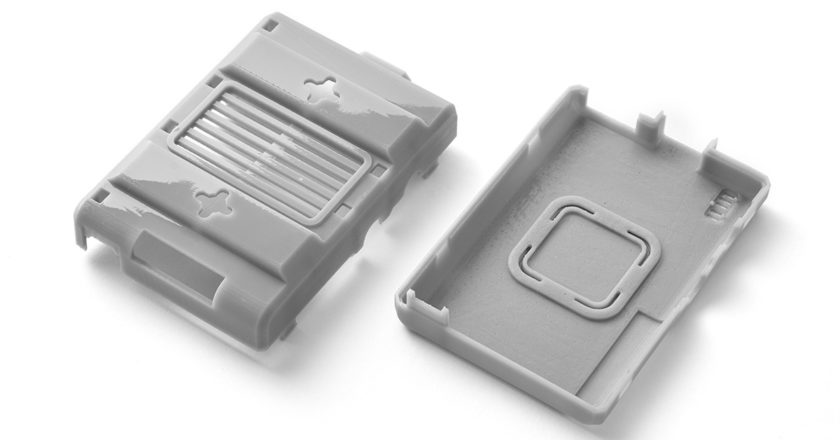

Other benefits of 3D printed jigs and fixtures include weight reduction (via high-strength plastic construction), ergonomic superiority (via customizable item contouring and shaping) and reducing overall complexity during the manufacturing process.

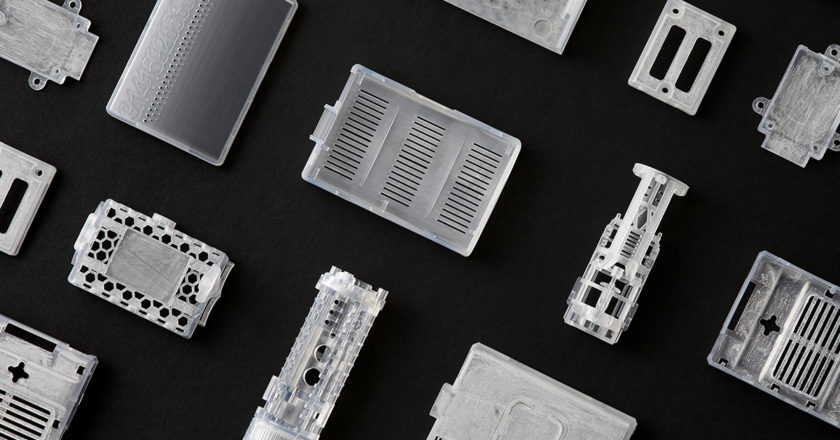

Here are examples of jigs that you can 3D print today:

Router Corner Jig

Built with black versatile plastic, a SLS nylon 12, this woodworking tool is designed to create precise cuts around angular corners during woodworking. A workshop essential, this 3D-printed tool allows users to make consistent cuts around edges when using a Router tool.

Cutting corners has never been easier thanks to this corner jig, which holds to the corner of your working piece to guide cuts at an exact and consistent radius.

Rotary Tool Drill Bit Sharpener Jig

Constructed with multi-jet fusion plastic, smooth black nylon 12, this rotary drill bit sharpener tool is the DIYers dream. This jig sharpens dull drill bits to their original condition by crafting a new cutting edge on the side of the tool. The process is simple: the jig attaches to a rotary tool and a grinding disc.

Then, the drill bit is inserted into the jig at the correct angle. The jig, in conjunction with the abrasive disc, proceeds to grind the drill bit to the user’s preferred degree of sharpness in seconds.

Center Point Finder Jig

This time-saving jig tool streamlines your assembly processes by allowing you to locate the midpoint of objects with varying levels of thickness. Made of durable red versatile plastic, a SLS nylon 12, the Center Point Finder Jig works according to a simple process: the jig is placed on top of an object that the user wants to measure, then the jig is twisted until the pegs cannot move any further. Then, the indicator in the center of the jig signifies where the midpoint of the object is.

Ready to Save Money for Your Company?

There has never been a better time to invest in jigs, fixtures, grips, and other tools that can save your company time and money when manufacturing. Typically, a jig or fixture would be sent away to be produced by a trained machinist for days at a time.

Today, 3D printing has cut down production times and created a more affordable alternative for manufacturers in need of custom-made assembly tools.

Interested in learning more about how 3D printing can impact your business by increasing productivity and lowering production costs? Get in touch today to learn how Shapeways, the leading end-to-end 3D printing fulfillment platform, is helping millions of companies leverage 3D printing to scale their businesses.

The post How 3D Printing Jigs and Fixtures Transforms Manufacturing appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing.