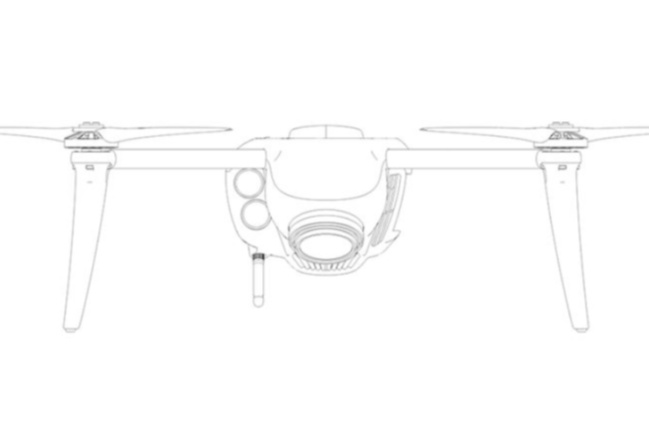

Kespry provides drone-based aerial intelligence for industrial use; drone parts 3D printed with Shapeways.

Sometimes referred to as unmanned aerial vehicles (UAVs), drones have been in use by the United States military since the turn of the century. Nowadays, manufacturers around the world are mass-producing drones for intelligence, security, parcel delivery, and even leisure.

But commercial-grade drones are prohibitively expensive. Many are still in the prototype phase. Those that are available are proprietary and are dependent upon long and costly supply chains. Thankfully, 3D printed drones are quickly becoming a reality — and they’re a significant opportunity for drone-based businesses to cut costs without cutting corners.

Cutting the Costs of Drones

Many consumers can readily afford miniature drones — some even sell for under $50. But drones capable of commercial applications have been out of reach for most businesses.

With the integrated technologies they need to function and the power to carry payloads like cameras and packages, commercial-grade drones can cost in the tens of thousands of dollars.

Thankfully, 3D printed drones are a solution to the cost problem. Instead of paying a premium for a finished product, businesses can print parts using a printing service and assemble drones to save substantially on costs.

3D Printing Goes Mainstream

3D printer sales have skyrocketed, and they’re only growing. By 2030, experts expect at least 100 million 3D printers to have been sold. Soon, 3D printers will be available in libraries and other public spaces, and people who can afford them may even have 3D printers in their homes. With the advent of mainstream 3D printing, devices like drones will be more accessible than ever.

3D printed drones can be constructed in parts by hobbyists. But 3D printing promises to deliver even better results for businesses. According to one study, 70% of the companies surveyed had increased their investments in 3D printing in 2018. That, compared to just 49% in 2017.

Businesses interested in expanding their drone capacities through 3D printing technology must measure the costs and benefits before investing. This technology is advancing rapidly every year.

Regardless, healthcare providers, delivery companies, energy producers, retailers, real estate firms, and even agribusinesses can all benefit from drone technology. Those that invest in 3D printed drone technology early will reap the benefits and gain an edge over their competitors.

Furthermore, most businesses won’t need to install 3D printing technology on-premises. Instead, they can rely on a 3D printing service to deliver all the products they need.

The Benefits of 3D Printed Drones

With so much attention being paid to drone technology, one would expect more business to be incorporating drones into their operations. But drone technology has been inaccessible for most businesses, especially small and medium-sized companies that already have heavy investments in their legacy operations.

The most significant barrier is the cost. Despite miniature drones becoming affordable for consumers, most businesses still need more advanced drone technology to harness any benefits. Advanced drones come with a hefty price tag.

3D printed drones stand to change all that.

Here are a few of the many benefits businesses can enjoy because of the combination of 3D printing and mainstream drone technology:

Cost Savings

First and foremost, 3D printing will help businesses save dramatically on costs, regardless of how they apply it. In one use case, a developer of automated water sensor systems reached a total savings of 86% in time and 95% in cost by leveraging 3D printing technology.

Construction companies, car manufacturers, and engineering firms are all realizing cost savings, as well. For companies that need a drone fleet to streamline their operations, there’s no better technology to employ to help the bottom line.

Customization, Modification, and Upgrading

When you order drones directly from a manufacturer, you get what you pay for. They may have a variety of models and some elements of customization, but you are still beholden to their offerings and their processes.

If you need to fix, upgrade, or modify your drone, you must reach out to the manufacturer and pay for it.

With 3D printing, you can customize, modify, and upgrade your 3D printed drones as much as you like. You can obtain 3D printing blueprints through numerous sources. Some are proprietary, but there are open-source files available as well.

Fast and Easy Repairs

If you’ve ever taken your care to the shop and been told they need to order a part to fix it, you can understand why businesses struggle when their commercial technology requires the same service.

When you 3D print drones, you typically do it in phases, printing each part and assembling the device afterward they are completed. Because of this process, you never have to order parts to fix your drones. Simply print a new part and fix the machine as necessary, saving your businesses time and money.

A Multitude of Materials

There is a wide range of materials available to use with 3D printers. Some of them are appropriate for drone technology, while others are best used for other applications.

For industrial 3D printing, some of the best materials are:

- Plastics (PET, Nylon, ABS)

- Resin

- Gold and Silver

- Titanium

- Aluminum

- Stainless Steel

- Ceramics

- Graphite and Graphene

Naturally, the types of materials you can use will depend on your project and the availability of the right printing technology. Drones, for example, can be made with plastic, aluminum, and other metals.

Because of their complexity and fragility, you may not be able to print some drone parts using these materials, especially if you intend to incorporate advanced computing systems into your drones.

Quantum-Systems develops technologically advanced drones for mapping, surveying and security applications; parts printed by Shapeways.

The Commercial Applications for 3D Printed Drones

Once printed and assembled, the commercial applications of drones are almost limitless. Some entrepreneurs are making a killing as drone photographers. But on a macro-economic scale, drones could change the way we shop, buy, communicate, and stay safe.

After the FAA opened its drone registration website, 300,000 drones were registered within the first month. Some were registered by consumers, but many more were registered by businesses looking to capitalize on the technology.

Here are just a few of the possible commercial applications of 3D printed drones:

Agriculture

Drones have the potential to revolutionize agriculture, but farmers must always be concerned about the bottom line. Now that 3D printed drones are becoming widely available, more and more farmers can save money in the investment.

Farmers can use drones to survey and inventory their crops, spray pesticides, spread fertilizers and seeds, and even monitor livestock. Essentially, drones can make time-consuming farm activities much more efficient.

Construction

Architectural and construction firms can use drones to create 3D models of a landscape. The architect can then use that model to design their building with complete accuracy. What architects could once only do with an expensive helicopter ride can now be done remotely with a small device.

On the construction side, drones can be used to monitor construction sites and deliver parts and products to workers high in the air, among other tasks.

Delivery

The prospect of drone delivery is perhaps the most explored application of this technology. With so many consumers shopping online, ground-based delivery is struggling to keep up with demand.

Amazon may be able to afford a proprietary fleet of delivery drones, but small businesses need a more cost-effective option. Whether it’s a new fuse, a local magazine, or even a pizza, 3D printed drones can enable any business to deliver its services.

Emergency and Healthcare Services

Drones have the potential to save people’s lives. They can deliver medical supplies to people in remote areas and surveil dangerous situations before emergency personnel move in.

With advanced computing technologies, drones can even be used to locate criminals on the run and people in distress.

Media and Photography

Photography and videography are two applications for drones that are already widespread. Consumers use drones to create amazing videos and photographs. But businesses can use them to create advertisements and video marketing content.

Wireless Internet

In areas that are hit by disasters, and in rural areas where robust internet infrastructure is lacking, drones can be employed to deliver wireless internet services quickly.

Internet service providers can 3D print a drone fleet and outfit them with broadcast technology in case of emergencies. Of course, they can also print drones on demand and offer emergency Wi-Fi as a service.

Adopting 3D Printed Drones

There are still some barriers to the widespread application of 3D printed drones.

Regulations are still being weighed and measured, and the public still has both safety and ethical concerns surrounding drone technology — but because of 3D printing, drones will only become more commonplace as more and more businesses adopt them.

The post 3D Printed Drones are Making Drones More Affordable appeared first on Shapeways Magazine.

36 Replies to “3D Printed Drones are Making Drones More Affordable”

Comments are closed.