Glen Hinshaw’s path to 3D printing is more circuitous than most. He used to ride in professional cycling circuits, was on the US Postal cycling team, founded a circuit board transport company, was a registered tax planner, was the manager of F1 driver Scott Speed, managed world tours for the Rolling Stones and U2, worked for the US Olympic Committee, managed an outdoor signage company as well as a games company. Along the way, Glen founded esoles that became a pioneer in 3D scanning soles using conventional means to manufacture them in stores and founded a leading custom bicycle fitting center. For nearly 15 years now Glen has been trying to make the in-store manufacturing of orthotics and custom shoe soles a reality. He came to 3D printing not because he was interested in the technology but because it could potentially make his dream of custom footwear for everyone a reality. With his startup RESA, he is trying to realize in-store manufacturing of 3D printing, and we spoke about his journey there.

How did you get started in 3D printing?

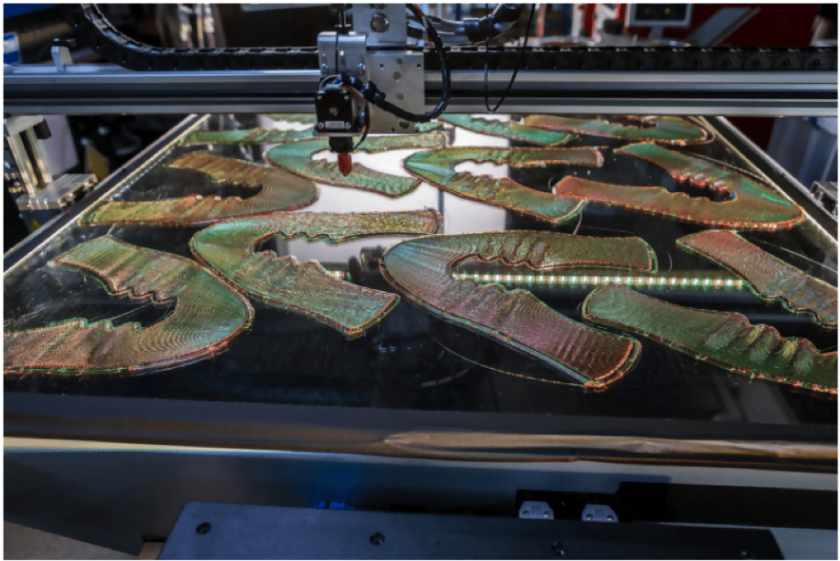

I wanted to improve the way custom insoles were made. After spending over a decade using traditional injection molding and CNC milled processes, we learned about AM and began to refine the process for our specific use case. That included designing custom internal structure forms, shaping the way the insole is built to improve performance and reduce production time. Ultimately we got the entire process down to under an hour, Using a process that we can use right there in the retail environment.

Deploys on-premise 3D foot scanning / Custom design / 3D printing systems to retail and medical locations. Using our own unique scanning technology and use our own custom high speed FDM machines.We provide customized orthotic insoles under $140 USD; ready-to-wear in 1 hour or less.

What partners are you looking for?

Banking on retail in the 21st century is a fairly radical idea for many investors. What we have seen is making insoles onsite is really popular with customers, met with excitement and return orders well beyond what we ever imagined. With AM and our FDM processes, our margins can support more growth, with a much lower capex.

For this to grow, we need Investor(s) and industry leaders in both hardware and software technology, who are not afraid to embrace retail 2.0.Our industry talk about ‘on demand, custom, on-site manufacturing’ as the wave of the future, people are surprised that we have already successfully proven high margins and customer demand far greater than expected for our custom footcare and footwear.

What is the advantage of a 3D printed insole?

Thankfully it’s easy for people to understand the advantage of 3D printing insoles, it’s perhaps one of the most simple use cases. We all know that 3D printing is perfect for making every part unique, and the best insoles are ones that are individually fitted to not just the customer, but to their activities and even their specific footwear. Its an obvious match! .

And of course we have the data to back this up. We didn’t just offer our product to the public and see sales, we had a national trial program that sold more than 50,000 pairs of insoles!

What is the potential?

At the most customer focused level, there is the opportunity for almost anyone to get access to a level of footcare that before many would have found prohibitively expensive. And when over 39% of adults experience foot pain, we know thats not a small problem or a small market.

At the same time, retail must transform, those who do not embrace Retail 2.0 will not survive. Resa is a company offering a product that engages customers and fulfills their needs in a way that is actually made more effective by being face-to-face. We are also able to use the data that customers share with us to make them Happy, not just for insoles, but for other products in the footwear space. With the most highly-evolved, most reliable footcare technology ever developed, we believe the world market can all benefit from our foot shape imaging and custom footwear/foot care products and services, over 14 billion feet worldwide.

Quite simply because having an end-to-end, face-to face process is much better at driving customer engagement.Because of direct customer interaction, we are able to capture far higher quality scans, that lets us provide a better product, with far higher satisfaction rates. And along the way we get to educate and entertain the customer, learn from them and better tailor our products to them. At the core we aim to be customer focused this means interacting with your customers, there is no better way to do that than in store. And it’s the best customer experience if at the end, you can hand them their product.

The conventional ways to make insoles mentioned earlier have lots of limitations, either they are cheap but not custom, or you can have semi-custom and more expensive, or fully custom but you wait 2-6 weeks and it’s very expensive (not to mention the waste and mess if you are milling foam!) 3D printing lets us offer fully custom at point of scan, but at a much lower price, with no mess and in under an hour.

We use a custom TPU blend, and in the future we will use more recycled or even biodegradable polymers.

Understanding how and when to use 3D printing. There is already wide use of 3D printing for tooling, but it takes time for designers and engineers to learn what works and what doesn’t when it comes to 3D printing for end use consumer products.

What is holding back 3D printing generally?

It’s not technology… Now don’t misunderstand. We need new and better 3D printing technology, but just as in footwear, it’s the lack of knowledge around how to successfully exploit the process that is holding this industry back.

“Can you 3D print this?”, is an easy question. “Should you 3D print this?” is a much harder question.

Don’t fall into the trap of thinking that 3D printing is a magic black box that just produces finished shapes. It’s a manufacturing process, and like any process you need to understand how and when to use it.

We are already working on research to better understand how to change the way we build our insoles, by using machine learning and AI we can change the internal structure of our insoles to improve comfort, better absorb impact and even improve long term health outcomes for our customers.And the Team at Resa care about our long term impact on the environment, 3D printing does produce less waste, but long term we need to not just use more recycled and re-processed polymers. We need to move to polymers that are actually part of the natural environmental cycle, like bio-polymers. We are all excited to see the fruits of the investments in new bio-plastics and other biodegradable materials for 3D printing.

The post Interview with RESA’s Glen Hinshaw on 3D Printing Shoes appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing.