Industrial 3D Printing for High-Performance Parts

One of the most exciting aspects of exploring our platform at Shapeways is learning more about how users on all levels are innovating today, and how you might be able to expand your own concepts and designs further through 3D printing. There are a variety of different, affordable services and products offered; however, one of the most important facets that must always be considered — from Shapeways to the entire 3D printing space worldwide — is materials. You can modify printers and write new software all day long, but without a good selection of feedstocks to choose from, quality results are nearly impossible.

BASF (known as a worldwide leader in development and production of chemicals) began partnering with Shapeways this year in providing new materials through their BASF 3D Printing Solutions subsidiary. Our new Powered by Shapeways platform enables users to choose from BASF’s Forward AM materials, expanding accessibility and options for high-performance parts.

The new material portfolio includes Ultrasint TPU01, Ultrasint PP, Ultracur3D RG 35, and HP High Reusability PP.

Ultrasint TPU01

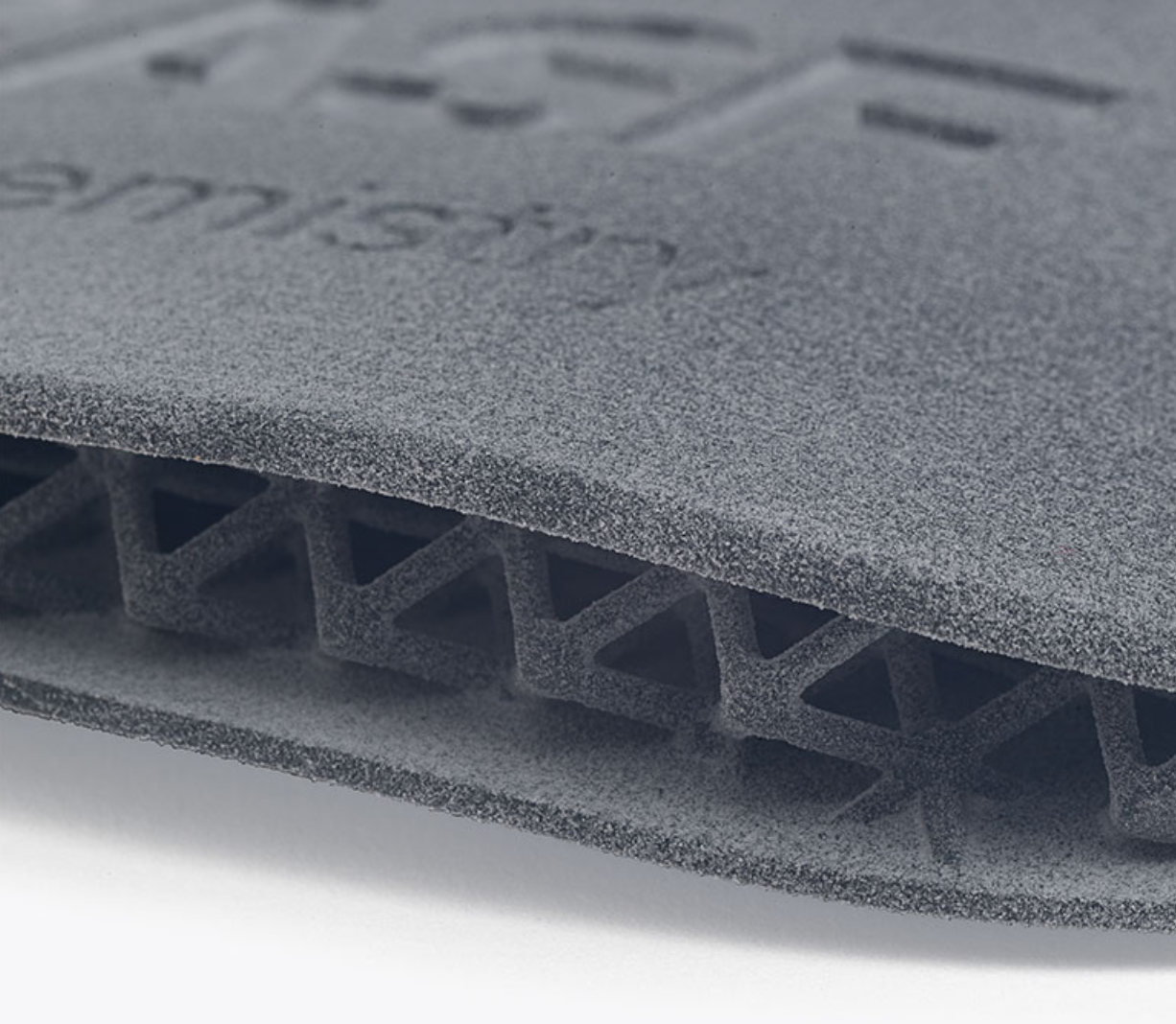

Ultrasint industrial grade powders are meant for 3D printing complex geometries that are accurate, strong, and durable. This thermoplastic polyurethane material is suitable for 3D printing functional end-use components, and is recommended if you require excellence in quality and flexibility for parts, along with the following features:

- High level of detail

- Good surface quality

- Recyclability (Ultrasint TPU01 offers up to 80% reusability ratio)

- Airtight parts (down to 1mm wall thickness)

- UV resistance

- Hydrolysis resistance

Approved for contact with skin, TPU01 is popular in automotive applications due to the open lattice structure encouraging both heating and cooling for interior parts like headrests or seats. Materials can be customized for individuals, and especially in areas typically experiencing heavier loads. Many of the best advantages of 3D printing technology can be used with TPU01 in particular, to include exponentially less time spent in development, production, and assembly time — along with elimination of tooling requirements and cost. Texture can be customized in terms of hardness/softness, and a variety of accompanying finishing options are offered too.

Another unique

benefit of TPU01 is that it can be used to 3D print protective gear for

the automotive industry; for instance, a protective glove was created for

workers at Jaguar Land Rover, offering support to prevent injuries due to

repetitive tasks. This type of gear is strong, yet lightweight and can be

completely customized for the wearer, including special modifications for the

job requirements of the individual. Again, this design is possible due to the

flexible lattice structure of the material. While it is flexible, hardness can

also be customized during the design process.

3D printing is employed in many footwear applications these days, and by users of widely varying experience and resource levels—from leading sports shoe companies to designers fabricating elegant flats or heels at their studios or from home workshops. Midsoles typically represent the 3D printed portion of shoes, with TPU01 allowing for consumer-specific customizations for greater comfort — designed around the wearer’s step, gait, pressure, and support — whether for sports, running, or other needs. Shoes can be made quickly, affordably, and on-demand.

TPU01 can also

be used to 3D print midsoles that are eco-friendly, requiring less material, as

well as offering improved aesthetics and performance. Personalized touches can

be applied afterward with a variety of different finishes and color choices.

Download the material data sheet from this page.

Ultrasint PP nat 01

A polypropylene material suitable for rapid prototyping as well as large-volume production of smaller parts, Ultrasint PP is a popular and affordable plastic with good market recognition. This material yields parts with excellent quality, balanced mechanical properties, and liquid, hydrolysis, and chemical resistance.

Ultrasint PP is

meant for production of smaller components like fluid reservoirs,

interior and exterior automotive parts, air ducts and piping, clips, covers,

hinges, and more. Parts like sensor covers can be made for critical aerospace

applications also, with prototypes fabricated from the same material and

process as the functional part. Live-hinge and snap-fit “barb” fittings can be 3D

printed too, with options for color and surface.

Download the material data sheet from this page.

Ultracur RG 35

Ultracur RG 35 is a highly reactive photopolymer suitable for a variety of parts used for multiple purposes, to include:

- Connectors

- Snappers

- End-use components

Recommended for parts that require rigidity, Ultracur RG 35

offers excellent resolution in printing, low shrinkage, accuracy, and both

speed and ease in production.

Download the material data sheet from this page.

HP High Reusability PP

A material specialized for use in HP’s production-grade Multi Jet Fusion 3D printers, HP High Reusability PP is suitable for making parts that are chemically resistant like piping and fluid systems, as well as automotive parts for the interior, exterior, and under the hood.

Download the material data sheet from this page.

Here at Shapeways, we have always offered a rich foundation for providing a wide range of materials suitable for industrial use. And while there are certainly no rules within the 3D printing realm about using (as well as continually developing) and experimenting with materials, our partnership with BASF has yielded a treasure trove of quality materials for the automotive industry, as well as for critical applications used in aerospace, architecture, and medicine. Recently, our team has also focused on offering 3D printing for robotics and drone applications.

Whether you are a busy designer or an engineer hoping to have a prototype or functional part 3D printed quickly, you will find an inspiring range of materials available at Shapeways. Without having to invest in industrial printers or materials on your own, you can benefit from our long-term experience and investment in proprietary, advanced technology.

The post Industrial 3D Printing for High-Performance Parts appeared first on Shapeways Blog.

U.S. Army Lab and Texas A&M researchers develop ‘self-healing’ polymer 3D printing materials

Forward AM and Photocentric launch joint portfolio of 3D printing visible light photopolymers

RIZE debuts RIZIUM Glass Fiber filament for full-color 3D printing

BASF Forward AM Materials: Ultrasint & Ultracur3d Comparison Guide

Shapeways is pleased to have partnered with BASF to bring you access to four Forward AM materials: Ultrasint® PP nat 01, Ultracur3D® RG 35, Ultrasint® TPU01 and HP High Reusability PP enabled by BASF. These durable and versatile materials facilitate a high level of design complexity and accuracy, producing functional, resistant prototypes and end parts with first-rate surface quality. Common applications for these materials include automotive, industrial, aerospace and consumer goods.

Here are some details on each of these four material

options, and a comparison guide to help with your material selection process.

Ultrasint®

PP nat 01

Polypropylene (PP) is one of the most commonly used plastics materials printed using Selective Laser Sintering (SLS) technology. Highly flexible and durable, it has a low moisture absorption rate and is resistant to most acids and bases, which makes it a great choice for parts with water contact. Ultrasint® PP nat 01 suits a range of applications from healthcare and orthopedic products to electronic and automotive parts and allows for post-processing such as thermoforming and sealing. It is a sturdy material that is well suited to industrial parts and production.

| IDEAL APPLICATIONS: |

| Pipes and Ducts |

| Water Manifolds and Reservoirs |

| Economic and Functional Prototypes |

| Multi-Purpose Industrial Goods |

| Durable Jigs and Fixtures |

Ultracur3D®

RG 35

This rigid, medium viscosity photopolymer is great for printing high-performance, functional and multi-purpose parts using Stereolithography (SLA), Digital Light Processing (DLP), or Liquid Crystal Display (LCD) machines. Parts produced with Ultracur3D® RG 35 are able to maintain extreme accuracy. It is a solid, tough material and is recommended for functional parts such as air ducts, electrical sockets and connectors.

| IDEAL APPLICATIONS: |

| Snapper |

| Air Ducts |

| Electrical Sockets |

| Thermoforming Molds |

| Connectors |

| Jigs and Fixtures |

Ultrasint®

TPU01

Ultrasint® TPU01 is a multi-use thermoplastic

polyurethane that typically comes in white and printed using Multi Jet Fusion

technology. It is a highly flexible material with excellent shock absorption,

making it ideal for footwear and other elastomeric parts. It is capable of producing

a high level of structural detail and intricacy and is UV and hydrolysis

resistant. It has excellent surface quality, high process stability and

throughput and its flexibility opens it to a myriad of uses that include

sporting goods and protection as well as interior automotive components and

orthopedic models.

| IDEAL APPLICATIONS: |

| Sporting Goods |

| Footwear |

| End Use Automotive Parts |

| Lattice Structures for Custom Performance |

HP High Reusability PP enabled by BASF

HP 3D HR PP is a highly versatile and durable

polypropylene material. It is chemically resistant and has a low water

absorption rate, which makes it a great choice for piping, fluid systems and

containers. It is the HP 3D material that costs the least and is very easy to

process, which increases productivity and reduces waste. Because it is both cost-effective

and functional, the material is well suited for prototypes as well as end parts.

It is a highly flexible material that is weldable to other PP parts, expanding

its range of applications from the automotive industry to the consumer goods

sector.

| IDEAL APPLICATIONS: |

| Piping and Fluid Systems |

| Containers |

| Interior and Exterior Automotive Parts |

Material Properties: Ultrasint® PP nat 01, Ultracur3D® RG 35, Ultrasint® TPU01 and HP High Reusability PP

Take a side-by-side look at each of these

materials’ properties below:

| Tensile Strength X | Tensile Strength Z | Heat Deflection Temp (0.45 MPa) | Tensile Modulus X | Tensile Modulus Z |

Elongation at Break X |

Elongation at Break Z |

|

| Ultrasint® PP nat 01 | 28 MPa | 28 MPa | 102 °C | 1400 MPa | 1400 MPa | 30 % | 10 % |

| Ultracur3D® RG 35 | 49 MPa | 49 MPa | 84 °C | 1990 MPa | 1990 MPa | 4 % | |

| Ultrasint® TPU01 | 9 MPa | 7 MPa | 75 MPa | 85 MPa | 220 % | 120 % | |

| HP High Reusability PP | 30 MPa | 30 MPa | 100 °C | 1600 MPa | 1600 MPa | 20 % | 18 % |

Ready to give these materials a try? Upload your model here to get an instant quote.

The post BASF Forward AM Materials: Ultrasint & Ultracur3d Comparison Guide appeared first on Shapeways Blog.

Forward AM expands 3D printing materials portfolio with XSTRAND acquisition

DyeMansion raises $14 million to “drive the transformation” of additive manufacturing

Lubrizol Buys into 3D Printing Parts and Services via Avid Acquisition

The Lubrizol Corporation has purchased Avid Product Development, a 3D printing and engineering services company, marking a significant development for additive materials and the larger industry as a whole.

While it may be best known for its engine oils, Lubrizol is a roughly $6.5 billion specialty chemical company owned by Warren Buffet’s Berkshire Hathaway. As such, it is one of a number of chemical producers that have been increasing their stakes in the 3D printing materials space, the biggest of which is BASF. The Ohio-based firm has already released its own additive feedstocks (specifically thermoplastic polyurethanes for fused filament fabrication and Multi Jet Fusion), but this acquisition marks a strong move for Lubrizol, as it expands from a material manufacturer to an engineering, 3D printing and post-processing service provider.

Based in Loveland, Colorado, Avid offers design for additive manufacturing, as well as prototyping and production using selective laser sintering, Multi Jet Fusion, fused filament fabrication and stereolithography. Additionally, the company provides post-processing for 3D printed parts. The company serves the footwear, consumer goods, industrial and medical segments and won the 2019 Colorado Company to Watch award. According to a press release sent to 3DPrint.com, Lubrizol plans to combine its expertise in materials, applications and testing with the aforementioned offerings from Avid in order to accelerate 3D printing adoption in key industries.

Gert-Jan Nijhuis, General Manager of 3D Printing Solutions at Lubrizol Engineered Materials, said of the deal:

“Lubrizol continues to invest in opportunities that bring new differentiated solutions to our customers. The acquisition of Avid Product Development greatly enhances our ability as a 3D printing solution provider, offering complete product solutions from material development to printing and post processing services, delivering end-use products for our key markets.”

As industrialized nations purportedly strive to shift from fossil fuels to renewable energy sources, oil companies may be looking to supplement demand through petrochemical markets. ExxonMobil admitted as much in a 2018 investor report, stating an expected 30 percent increase in petrochemical demand by 2025.

In turn, not only are we seeing an increasing number of major chemical companies enter the 3D printing industry, but we are seeing them diversify within that space as well. BASF has made the biggest movements, putting money into three different 3D-printed parts makers by partnering with Shapeways, investing in Materialise and acquiring Sculpteo. Mitsubishi Chemicals is also trying its hand at 3D printing parts through a pilot program with AddiFab.

By purchasing Avid, Lubrizol gets out ahead of a number of other chemical companies not described so far, including Dow/DuPont, Eastman, SABIC and more, who seem to be more focused on making materials at this point than using them. However, we have also witnessed a number of investments by companies like DSM and Arkema into new technologies and startups that could greatly expand their foothold in 3D printing once those startups take off.

All of these players are changing the landscape of the 3D printing industry, likely into a more industrially focused space. How that will look in the years to come is anyone’s guess, particularly given the uncertainty of global events at the moment, but the impact will be impossible to overlook.

The post Lubrizol Buys into 3D Printing Parts and Services via Avid Acquisition appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing.