BASF and Photocentric Launch Materials for Visible Light 3D Printing

BASF’s 3D printing unit, Forward AM, has advanced its partnership with Photocentric to develop and launch a materials portfolio specifically tailored for the LCD-screen based daylight 3D printers from Photocentric. The partnership combines the latest materials and 3D printing technology, improves the quality and efficiency in 3D printing components, and aims to further enable the industrialization of the additive manufacturing industry.

“From the very beginning of our cooperation, together we have aimed to extend the possibilities of advanced photopolymer solutions to address the enormous spectrum of applications opened up by the outstanding performance of this Additive Manufacturing technology. We believe the combination of the expertise gained through decades of BASF research into 3D printing materials, our unique material portfolio, and Photocentric’s remarkable printer technology, genuinely has potential to enable cost competitive parts printing and thus make mass-manufacturing of functional end-use parts a reality,” explains François Minec, Managing Director BASF 3D Printing Solutions.

“The new chemistries we have harnessed for our product offering enable us to meet our customers’ very high mechanical performance demands and realize their mass scale applications. At the same time we are intentionally offering industry-disruptive prices on formulated bulk resin to the market: Jointly we want to move the Additive Manufacturing business towards higher productivity and lower prices per printed part,” adds Dr. Piotr Bazula, Global Product and New Business Development Manager Liquid Formulation Solutions, BASF 3D Printing Solutions.

The two companies had been collaborating on optimizing photopolymer resins and printer parameters, and the next step has been to go to market together with a range of high performance photopolymers: ‘Ultracur3D Powered by Photocentric’. For BASF, this is another specialized application for its Ultracur range of materials, which can be applied to DLP, LCD and SLA based 3D printing technologies.

“Photocentric is deepening its partnership with BASF to facilitate the custom mass manufacture of components in a wide variety of industries. Together we have created a unique combination of software, hardware and chemistry that removes obstacles to using Additive Manufacturing in mass production. Working with Forward AM, we have developed a portfolio of products that delivers the required functional properties perfectly, enables high-resolution mass manufacture, and thereby adds real customer value,” says Paul Holt, Managing Director, Photocentric Ltd.

“This extended range of high performance materials now allows our customers to take full advantage of the large build volume, speed and reliability of Photocentric printers, to move towards the cost-effective, large-scale production of end-use parts,” comments Sally Tipping, Sales Director, Photocentric Ltd.

Ultracur3D EPD 1006 Powered by Photocentric will be the first in an initial set of ten products specifically developed for LCD daylight technology, and the partnership will look to expand offerings within the portfolio progressively.

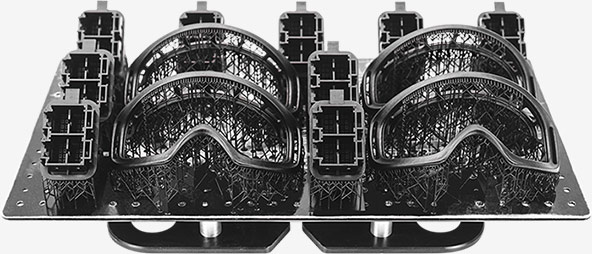

BASF Ultracur material used in the LC Magna. Image Courtesy of Photocentric.

Photocentric, founded in 2002 and headquartered in the UK, has disrupted the vat photopolymerization 3D printing market with its Liquid Crystal 3D printers and material solutions that rely on LCD-screens (using visible or low light spectrum) to cure special photopolymers to print high quality parts, that significantly improve the speed and cost efficiency of 3D printing production, particularly in digital dentistry.

Video courtesy of Photocentric

The polymer market is set to generate $11.7 billion in 2020, as per SmarTech’s “Polymer Additive Manufacturing Markets and Applications: 2020-2029” report, and BASF, a leading polyurethane manufacturer and the world’s largest chemical company (by revenue), has been expanding its presence in the 3D printing industry, to include specialized materials providers, hardware and software providers, as well as service bureaus.

In 2019, BASF had introduced its new 3D printing brand ‘ForwardAM’ and, since then, has engaged in a number of partnerships, investments and acquisitions in the 3D printing ecosystem to expand its presence and offerings in the industrial AM market. The company acquired Sculpteo, partnered with Shapeways to combine the product creation platform’s proprietary technology with the range of additive materials from ForwardAM via a co-branded website; teamed with HP to develop materials for the Multi-Jet Fusion 3D printing platform, with Impossible Objects in its composite sheet layering technology, and with Origin and ECCO for footwear production; invested in Materialise for materials and software; invested in and partnered with PrismLab in the Asian market, with Essentium for Ultrafuse filaments for high-speed extrusion printing, as well as with Owens Corning for glass-fiber reinforced filament materials.

The post BASF and Photocentric Launch Materials for Visible Light 3D Printing appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing.

Forward AM and Photocentric launch joint portfolio of 3D printing visible light photopolymers

Smith College team wins Covent-19 Challenge with low-cost 3D printed ventilator design

Lumi Industries introduce open-source smartphone-based resin 3D printer

3D Printing Congress in Argentina: Novel Ideas and a Harsh Landscape Ahead

A new edition of the 3D Printing Congress in Argentina wrapped up last Thursday after two days of workshops, supplier stands and speakers talking about the challenges and solutions of manufacturing using 3D printing. From biomaterials to resins, 3D printing in the automotive industry, 3D medical simulators and biomedical inventions, some of the most innovative uses for the technology show that it is advancing in the country, albeit somewhat slower than expected.

Sergio Cavaliere, Product and Applications Manager for Advanced Machine Systems (AMS), said to 3DPrint.com: “The local market is volatile, complex and caged by controls, yet at the general manufacturing level we notice that companies have begun acquiring additive manufacturing technology, perhaps not at the hyper expectation levels we forecasted five years ago, still, they know that if they don’t begin to use 3D printing, they will lose competitiveness.”

Held 6 to 7 November in the City of Buenos Aires, the event gathered more than 3,500 3D printing enthusiasts, professionals, and researchers who eagerly discussed how to achieve better, cheaper and more efficient results, as well as what’s on the horizon for local 3D printing companies. This year’s main themes focused on 3D printing in industry and biomedicine.

Last year, when the Mercedes Benz plant in Buenos Aires was looking to improve its production line of trucks and vans, they consulted Cavaliere and AMS. The manufacturing process specialists recommended they acquire an additive manufacturing machine to accelerate production. The local branch of the German vehicle maker soon began using a Stratasys F270 24/7 and in only 23 days created the devices needed for the manufacturing engineering of the assembly line.

“In general and around the world, almost 70% of all 3D printing is used for prototyping. However, this is not the case for Argentina, where industries are searching for ways to use the technology in manufacturing aids–like jigs, fixtures, platforms and tools (mainly in automotive). This means that they require more durable materials with high thermal and impact resistant qualities. And while most machines sold locally today are PLA printers that are very common for prototyping, they are not useful in manufacturing. That’s the reason our product sparked a lot of interest among attendees at the Congress,” suggested Demian Gawianski, CCO of Kodak 3D Printing during an interview with 3DPrint.com.

Gawianski considers that 3D printing know-how has been growing in recent years, more focused on industry and engineering applications. In 2012, Argentina-based Smart International began developing and manufacturing 3D printers and in 2018 they released Kodak’s Portrait 3D printer, a new professional 3D printing solution, which was developed through a global brand licensing agreement.

Furthermore, the team behind Kodak showcased parts that are being produced as part of their new segment, an alliance with renown polymer manufacturers worldwide, such as BASF, Owens Corning, Clariant, and DSM. “The pieces printed with our machines using BASF stainless steel are very alluring for manufacturers because they have 80% stainless steel and 20% of a polymer which after a few post-processes becomes 100% stainless steel,” explained Gawianski. “Our machines are certified to work with already established materials from large manufacturers, allowing our customers to develop engineering pieces with high resistance.”

Not to be missed was Juan Manuel Romero’s talk about his Game of Thrones spoons, made earlier this year exclusively and in partnership with HBO Latin America, just in time for the premiere of the world-wide awaited sixth and final season of the show. The innovative development even competed at Cannes’ International Festival of Creativity during the 2019 award season.

“3D printing offers infinite novel possibilities for jewelry creations, characterization, and improved quality. The precision approach of the machines is an advantage to more traditional methods of creating jewelry,” said Romero to 3DPrint.com. “Back in 2014 we realized that we needed to scale production without losing the design edge, and 3D printing gave us all that and more.”

Romero, the owner of Quimbaya, has been a goldsmith jeweler for over 10 years, yet he learned quickly that using 3D printing to go from design to molding makes a big difference towards his end product. He states that “morphologically, the jewelry design has no limit, while with conventional methods, the same level of accuracy could never be achieved.” For his Game of Thrones spoons, he used Photocentric’s Precision 1.5 machines to create the prototype and the molds that were then used to make the metal spoons. The four spoons (representing the most iconic houses of the series: Stark, Lannister, Targaryen, and Greyjoy) traveled from Argentina to Europe with HBO, they became a very popular and desirable item due to the visibly unique quality, traits and intricate work.

One of the most popular booths among attendees was PrintaLot. The company director, Mariano Perez, has underlined the success of his filaments: “Our client portfolio used to be made up mainly of hobbyists, and today we mostly get industrial market orders from companies that are driving the digital transformation of the industry”. In this sense, he adds that “we began working with other markets in the region, like Brazil, which has a big demand for our products.” One of the biggest orders the company got from Brazilian clients was a request for a new PLA color, the green-blue shade made famous by jewelry maker Tiffany.

“3D printing machines and materials are changing the production processes of different economic sectors and creating new business models. We also began reselling Wiiboox Sweetin, the gourmate food 3D printer, and Ultimaker, because we noticed many local entrepreneurs were searching for this type of solutions,” Mariano told 3DPrint.com.

In addition to the increasingly popular local 3D printer suppliers exhibiting the latest MakerBot, Formlabs, BCN3Ds, and Trideo (one of the most popular local brands), new and creative applications drew big crowds. Like a surgical simulator; 3D bioprinters to treat wounds in diabetic patients; bespoke 3D printed titanium implants, and the WalkingMaker, a 3D printer with wheels that extrudes material obliquely.

Nicolas Meer, co-creator of a pediatric surgical simulator for medicine residents said: “we spoke to pediatric surgeons who suggested the best way to teach the techniques of laparoscopy to students and future doctors was through a simulator, instead of waiting for a real case or practicing with animal parts. I have been working with 3D printers since 2012 so I decided to design and print a small simulator that wouldn’t cost more than $500.”

The post 3D Printing Congress in Argentina: Novel Ideas and a Harsh Landscape Ahead appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing.

New 3D Printing Resin Made with Nanodiamond Powder

Nanodiamonds are diamond particles produced by explosions, and are very thermally conductive. Nanodiamond powder is made up of non-toxic diamond nanoparticles, with a large surface, that are about 5 nm in size, and feature some interesting properties.

![]() Researchers Krzysztof Królewski, Aleksandra Wieloszyńska, Aleksandra Kamińska, and Katarzyna Kardacz from Poland’s Gdańsk University of Technology (GUT), wanted to investigate a particular property, and published a paper on their work, titled “Optical properties of daylight curable resin doped with nanodiamond powder.”

Researchers Krzysztof Królewski, Aleksandra Wieloszyńska, Aleksandra Kamińska, and Katarzyna Kardacz from Poland’s Gdańsk University of Technology (GUT), wanted to investigate a particular property, and published a paper on their work, titled “Optical properties of daylight curable resin doped with nanodiamond powder.”

The abstract reads, “In this paper a new material for 3D printing was elaborated on. Since diamond has very good optical properties, an idea occurred to us to apply it in a 3D printing process. A mixture of nanodiamond powder and standard 3D printing resin was created and several printouts have been completed. They have been tested for their abilities to transmit and absorb light in a wide spectrum of wavelengths. It turned out that nanopowder doped resin in comparison to standard one has worse optical properties. However, it shows that a mixture of resin and nanopowder can control optical properties of printouts.”

Fig. 1. Prototypes of 3D printed cylindrical lenses. L-R: convexo-convex lens, convexo-concave lens, plano-concave lens, plano-convex lens, and concavo-concave lens.

The team prepared and analyzed a new 3D printing material made out of diamond nanoparticles and amber 3D Daylight Hard resin from Photocentric, which caused unique optical properties. They fabricated a few examples of their material on the Liquid Crystal 10′ 3D printer, and then tested the optical properties, along with the optical properties of the Photocentric polymer resin for comparison.

Fig. 2. Prototypes of 3D printed spherical lenses. Bottom L-R: plano-concave lens, plano-convex lens, and convex-concave lens. The top row shows two convex-concave lenses.

“The 20 mm × 20 mm plates were printed as test samples which were prepared with different thickness (0.2 mm, 0.5 mm, 0.8 mm, 1 mm, 1.5 mm, 2 mm and 5 mm),” the researchers explained.

A spectrometer was used to obtain transmission characteristics of the 3D printed sample plates, in the 200-1100 nm wavelength range at room temperature. These characteristics are defined by, as the researchers wrote, “increasing transmission with decreasing the thickness of plates.”

Fig. 3. Two series of flat plates (first series at top and second at the bottom). The thinnest plate is on the left.

For the first series of 3D printed plates, the transmission was almost zero for light waves in the 200-400 nm range, while the greatest transmission was for those in the 800-1100 nm range. The transmission for series #2 was even higher, which was easy to see with thicker plates. These characteristics are comparable with those of other optical materials, such as fused silica, and are definitely appropriate for a number of optical applications.

“In the first series, the maximal transmission is 60% and 44% for 2 mm and 5 mm thick plate, respectively. In turn, in the second series, this value is 75% and 65%, respectively,” the researchers noted.

The team then determined the absorption characteristics for the plates, and found that the greatest absorption is for light waves in the 200-400 nm, due to their orange color; the lowest absorption was for waves in the 600-1100 nm range.

Fig. 8. One series of flat plates, printed from the mixture of resin and nanodiamond powder which was obtained by evaporating DMSO from the suspension with nanodiamond.

More plates were then 3D printed out of the team’s novel material of nanodiamond powder and resin. The researchers then went into a little more detail as to how they obtained, and created, the material.

“The nanodiamond powder was obtained by evaporating DMSO (dimethyl sulfoxide) from the suspension with nanodiamond,” they wrote. “Then the 66.835 g liquid resin was mixed with 0.069 g powder. First, the magnetic stirring was carried out for an hour and after that, the sonication was done for 45 minutes. The sonicator worked in pulse mode with power set at 10%.”

The team used a series of OCT measurements to evaluate the material properties of the 3D printed plates, and got single B-scans from three plates with diamond nanoparticles, and one without, for reference. The images show that because of nanoparticles being present, and “the lack of tendency to agglomeration,” the prepared material was in fact homogeneous.

Fig. 9. OCT image of the plate with nanopowder. There are scattering centers in the sample (bright spots in the image), which indicates the occurrence of diamond nanoparticles.

Fig. 10. OCT image of polymer used for printing. Lack of the scattering centers indicates no occurrence of the diamond nanoparticles.

“In this research we have shown that the presence of nanodiamond affects the optical characteristics of the mixture,” the researchers concluded. “It gives premises that other nanoparticles can modify the optical properties, especially absorption characteristics. Therefore, it may lead to new opportunities for a low-cost, quick and easy method for rapid prototyping of optical filters.”

Discuss this story and other 3D printing topics at 3DPrintBoard.com or share your thoughts in the Facebook comments below.

The post New 3D Printing Resin Made with Nanodiamond Powder appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing.

Photocentric releases LC Magna large-format LCD 3D printer

3D printing news sliced, European Space Agency, Optomec, and Carbon

3D Printing News Briefs: November 13, 2018

We should really call today’s 3D Printing News Briefs the formnext 2018 Briefs, as announcements from the show are numerous this week. EnvisionTEC, XYZprinting, BASF, and DSM all introduced new 3D printing materials at the event in Frankfurt today, and in the only news not related to formnext, Imerys Ceramics has announced a new range of ceramic feedstocks.

EnvisionTEC Debuting First 4K 3D Printing System

At formnext, 3D printer manufacturer EnvisionTEC debuted the industry’s first DLP-based 3D printer that uses a true 4K projector with UV optics tuned to the 385 nm wavelength. Available in three production-ready variations, with a gray body and a 2560 x 1600 pixel projector resolution, the Perfactory P4K 3D printer delivers highly accurate parts with an ultra-smooth surface finish. Additionally, the Perfactory P4K, has access to the rest of the Perfactory line’s versatile materials portfolio for production capacity.

At formnext, 3D printer manufacturer EnvisionTEC debuted the industry’s first DLP-based 3D printer that uses a true 4K projector with UV optics tuned to the 385 nm wavelength. Available in three production-ready variations, with a gray body and a 2560 x 1600 pixel projector resolution, the Perfactory P4K 3D printer delivers highly accurate parts with an ultra-smooth surface finish. Additionally, the Perfactory P4K, has access to the rest of the Perfactory line’s versatile materials portfolio for production capacity.

“The P4K is the highest resolution advanced DLP printer with the largest build envelope and deploys artificial intelligence in pixel modulation to deliver the highest accuracy parts with the smoothest available surface finish in the 3D printing space. This will deliver the next level of production-grade 3D printing solutions,” said Al Siblani, the CEO of EnvisionTEC.

The new Perfactory P4K will be on display at formnext all week.

XYZprinting Introducing New 3D Printing Materials

Another company introducing new materials at formnext this week is desktop 3D printing brand XYZprinting. In order to expand the capabilities of both domestic and professional grade 3D printers, the company is launching a new antibacterial PLA material, along with copper metallic PLA and Carbon PLA materials. The first of these can destroy up to 99% of bacteria, including E. coli and Staphylococcus aureus, and comes in four colors: white, red, yellow and neon green.

Another company introducing new materials at formnext this week is desktop 3D printing brand XYZprinting. In order to expand the capabilities of both domestic and professional grade 3D printers, the company is launching a new antibacterial PLA material, along with copper metallic PLA and Carbon PLA materials. The first of these can destroy up to 99% of bacteria, including E. coli and Staphylococcus aureus, and comes in four colors: white, red, yellow and neon green.

The copper metallic PLA, made of 65% copper powder, is a good alternative for hobbyists when it comes to sculpting metal for ornamental models. The material is being launched in conjunction with XYZprinting’s new nozzle, made of carbon hardened steel. Finally, the new Carbon PLA, which is also compatible with this new nozzle, is made of 10% carbon fiber, and its matte finish is ideal for showing off fine details. You can learn more about these new materials at XYZprinting’s booth D10 in Hall 3.1, where it will also be exhibiting its latest 3D printer, the da Vinci Color AiO, with a 3D scanner and optional laser engraver.

BASF 3D Printing Solutions Presents New Products at formnext

Germany-based BASF 3D Printing Solutions GmbH (B3DPS), a 100% subsidiary of BASF New Business GmbH, is also at formnext this week, to introduce several new materials for photopolymer and laser sintering methods, in addition to announcing some new partnerships and alliances. First, B3DPS is introducing flame-resistant Ultrasint Polyamide PA6 Black FR, Ultrasint PA6 Black LM X085, which is suitable for most current SLS 3D printers, and Ultrasint PP, a polypropylene with great plasticity, low moisture uptake, and resistance to liquids and gases. Additionally, B3DPS has also grouped its photopolymer materials under the new Ultracur3D brand name.

Germany-based BASF 3D Printing Solutions GmbH (B3DPS), a 100% subsidiary of BASF New Business GmbH, is also at formnext this week, to introduce several new materials for photopolymer and laser sintering methods, in addition to announcing some new partnerships and alliances. First, B3DPS is introducing flame-resistant Ultrasint Polyamide PA6 Black FR, Ultrasint PA6 Black LM X085, which is suitable for most current SLS 3D printers, and Ultrasint PP, a polypropylene with great plasticity, low moisture uptake, and resistance to liquids and gases. Additionally, B3DPS has also grouped its photopolymer materials under the new Ultracur3D brand name.

András Marton, Senior Business Development Manager at B3DPS, said, “Our Ultracur3D portfolio enables us to offer customers various UV-curable materials for 3D printing that provide far better mechanical properties and higher long-term stability than most available materials.

“These materials have been developed for functional components that are subject to high stress.”

The subsidiary also announced that it’s partnering with California company Origin and 3D printer manufacturer Photocentric to develop photopolymers and photopolymer 3D printing processes, and working with Chinese 3D printer manufacturer Xunshi Technology, which operates in the US under the name SprintRay, to open up new applications for the Ultracur3D range. Additionally, B3DPS subsidiary Innofil3D is partnering with Jet-Mate Technology in China and US-based M. Holland to distribute plastic filaments. Visit B3DPS at formnext this week at booth F20 in Hall 3.1.

DSM Announces 3D Printing Product Launches

In today’s final formnext news, science-based company DSM has unveiled two new high-performance materials for 3D printing structural parts. Somos PerFORM Reflect is a groundbreaking new stereolithography material for wind tunnel testing with PIV (Particle Imaging Velocimetry), and saves more than 30% post treatment cost by eliminating the need to apply PIV coatings to printed parts. In addition to helping customers conduct iterations and collect data more quickly, the resin could actually help break speed records for wind tunnel testing.

“Speed is crucial, whether in automotive, aerospace or other transportation design. Eliminating the need to apply PIV coatings is a major breakthrough for customers who are using PIV wind tunnel testing. It allows them to speed up their aerodynamic design optimizations. We are thrilled that our strategy of focusing on helping customers create their applications have enabled us to deliver such tremendous value. Overnight, Somos® PerFORM Reflect will not just set new speed records but new industry standards,” said Hugo da Silva, Vice President of Additive Manufacturing at DSM.

The company’s second new material is the thermoplastic copolyester (TPC) Arnitel ID2060 HT, which is perfect for the FDM 3D printing of structural parts for automotive applications. The material features a balance of prolonged high temperature resistance, flexibility, and chemical resistance against exhaust gas recirculation (EGR) condensate.

Imerys Ceramics Introduces EZ Print 3D Range of Ceramic Feedstocks

As part of the Imerys group, Imerys Ceramics designs, produces, and markets high-performance mineral solutions for the ceramic industries, and is making ceramic 3D printing easy with its new, unique range of ceramic materials called EZ Print 3D.

As part of the Imerys group, Imerys Ceramics designs, produces, and markets high-performance mineral solutions for the ceramic industries, and is making ceramic 3D printing easy with its new, unique range of ceramic materials called EZ Print 3D.

EZ Print 3D is available as a plug & play cartridge, so users can enjoy efficiency and ease of use when it comes to 3D printing. The materials are also available as a “ready to fill” ceramic feedstock, and have been tested on several 3D printers currently on the market. EZ Print 3D has a low firing temperature of 1220°C that’s compatible with most kiln temperature limits, and the genuine low porosity (<0,5%) of a porcelain. The technology is perfect for tableware and giftware applications, and the company plans to expand EZ Print 3D accordingly as 3D printing adoption grows. Imerys Ceramics also provides technical support and a dedicated team that’s competent in 3D printing to help customers.

Discuss these stories and other 3D printing topics at 3DPrintBoard.com or share your thoughts in the Facebook comments below.