Service bureau PrintLab is partnering with Autodesk for an exciting new competition for schools. The make:able challenge represents what should be a remarkable technological journey for students and teachers as they are invited to use either Tinkercad or Fusion 360 software (both options are products of Autodesk) and 3D printing to make free, assistive technology with the following directions:

“Design and make a product or prototype that improves the day-to-day life of someone who struggles with mobility in their hands.”

This comprehensive challenge—and learning experience for students—is centered around an online toolkit provided for students, including a teacher’s guide and accompanying lesson plans. Students are expected to team up into smaller groups and use the toolkit as a foundation for increasing their design skills, especially in 3D—with the use of Autodesk products. More importantly, though, the competition is designed to help them find meaning in their communities, whether locally or online, as well as learning about how individuals must cope with disabilities and can use assistive technology for a better quality of life.

Make:able toolkits also offer inspiration through the following:

- Stories and example solutions

- Worksheets and a variety of activities designed to encourage a human-centered approach and teach empathy

- Methods for encouraging design-based thinking for creating concepts and opportunities

- Directing students to tell their story through their work

- Designing, 3D printing, testing, and making changes to products

“Having supported hundreds of schools with 3D printing curriculum, we have witnessed firsthand some amazing student talent across the globe,” said Jason Yeung, Co-Founder of PrintLab. “It is our belief that this talent should expand outside of the classroom and be put to use on real-world challenges that have a positive impact on society.”

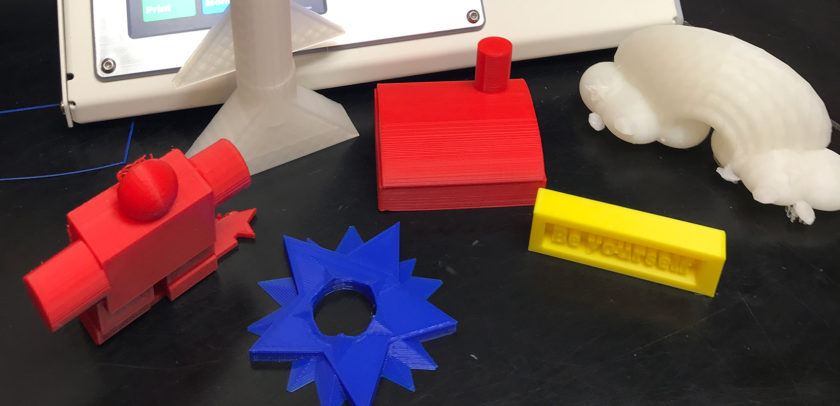

The key behind PrintLab and Autodesk partnering was to create an integrative program for schools to help encourage students in design and 3D printing, highlighting their work in both digital and AM processes.

“By participating in the make:able challenge, students will experience The Future of Making to help design and make a better world,” said Steven Parkinson, Education Manager at Autodesk.

Students ages 18 and under are eligible to participate in the make:able challenge, to be included in the following types of educational courses:

- Design and technology classes

- Science, technology, engineering, and mathematics (STEM) lessons

- After-school programs

- Workshops

- Distance and remote learning opportunities

Teachers who register for the make:able program will receive challenge toolkits on September 1st. The teacher’s pack includes development resources and guided lesson plans. Entries are to be judged by a panel of experts in April 2021, with prizes including 3D printers for winning teams.

Challenges like make:able stress both the importance of using innovation and 3D printing to do good in the world, as well as the importance of STEM education for the younger generations. Many projects are designed to interest more girls in 3D printing—a powerful tool for STEM—as well as creating workshops and specific STEM apps for kids. Find out more here.

[Source / Images: PrintLab]

The post Make:able Challenge: Design & 3D Print Assistive Technology for the Disabled appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing.