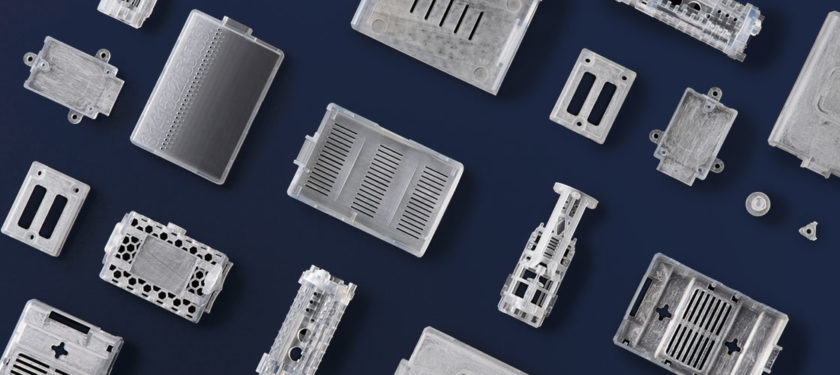

2019 was a banner year for Shapeways, as we continued to expand our capabilities through new partnerships and material launches. This year, we added over 20 new materials and finishes to our portfolio, providing new high-end 3D printing solutions for a multitude of industries. Curious about what we released in 2019? Here’s a look at some of the new materials we added this year.

MJF PA12 Glass Beads

PA12 Glass Beads is a glass-filled nylon printed with HP Multi Jet Fusion technology. This material offers high stiffness and high structural integrity. The glass particles make this material stiffer than MJF PA12, so products print without warping resulting in more structurally sound products for end-use applications. PA12 Glass Bead’s resilience and strength make it an ideal material for projects within the medical, robotics, and drones industries, particularly for applications like flat parts, fixtures, and tooling. It’s currently available in two finishes: Gray and Dark Gray.

TPU (Thermoplastic Polyurethane)

TPU is an excellent, cost-effective alternative to our premium elastomeric material, Carbon EPU. TPU’s elasticity and natural resistance to most every day wear make it an excellent candidate for automotive and medical use. It would work wonders as an insole, midsole, or helmet; and for robotics applications, TPU could be used for tubing, hoses, and seals.

PA11

PA11 is a biocompatible nylon material that is optimal for use in exterior medical applications such as customized orthotic braces and prosthetics. It is tensile, durable, and impact-resistant with a high elongation at break point. These properties make PA11 ideal for use in aerospace, automotive, and other high-impact applications.

MJF Black Smooth PA12

Utilizing Additive Manufacturing Technologies’ physio-chemical process, MJF Black Smooth PA12 creates smooth, semi-shiny, and watertight surfaces, sealing Multi Jet Fusion Plastic’s typically matte and porous surface. And since the finishing process is non-line of sight, even the internal cavities of complex parts can be smoothed. With this new material, it’s now possible to achieve less than 1 RA of surface roughness.

Accura® 60

This clear plastic produces rigid and durable parts with similar properties to molded Polycarbonate (PC). It has the ability for fine details making it apt for tough, functional prototypes, lighting components, medical instruments and fluid flow and visualization models.

Accura® Xtreme™

A material with similar physical properties to polypropylene and ABS, Accura® Xtreme is an ultra-tough grey plastic with outstanding durability, accuracy, moisture and thermal resistance and the ability for great detail. It is ideal for snap fit assemblies, enclosures for consumer and electronic products, master patterns for vacuum casting, and general purpose prototyping.

Accura® Xtreme™ 200

This white plastic is the toughest SLA material available and can replace CNC-machined polypropylene and ABS articles. It is perfect for projects that must withstand extreme, harsh conditions making it ideal for challenging functional assemblies. It can be applied to similar projects as Accura Xtreme as well projects that demand the highest durability like automotive parts, drill/tap applications, assemblies with self-tapping screws, enclosures for consumer electronic components, general purpose prototyping, and master silicone molding.

Copper

Copper is a precious metal that can be used in a wide variety of applications due to its unique properties. Copper’s initial appearance takes on an orange-red metallic color but eventually darkens by turning green in color through oxidation. This chemical reaction forms a protective layer on its surface making Copper highly resistant to corrosion and biofouling. While oxidation can create an antiqued appearance that may be desirable for creating ornamented and unique jewelry, Copper is most suitable for marine and aerospace applications and use in other harsh environments.

And that’s not all! Through our partnerships, we’ve given Shapeways users access to even more cutting-edge materials. Want to learn how we you can get access to our premium materials for your business needs? Reach out to our sales team today!

The post Here’s Every New Material We Launched in 2019 appeared first on Shapeways Magazine.